More shipping capacity through new Mörsch gas compressor station

Gas travels thousands of kilometres in international and national pipelines before reaching consumers. Thanks to compressor stations, gas is compressed and its pressure increased. This means that more gas can be transported through the pipeline. The shipping capacity of the pipeline increases – and therefore also the security of supply.

Our new gas compressor station Mörsch on the Nordschwarzwald pipeline is being built in Rheinstetten in the Hardtwald south of the radio mast between the L566, the B3 and the A5. Construction began in the autumn of 2021. Commissioning is planned for 2025.

Another important step in the commissioning process of the new Mörsch gas compressor station has been completed: The 72-hour test of all four compressor units – three gas compressors and one electric compressor – was successfully completed. The performance tests were also largely completed. The compressor station meets all standards and regulations. In addition, noise and emission measurements were successfully carried out.

Looking back over the past few months, much has already been achieved: The construction site setup area has been dismantled. The area next to the Mörsch compressor station was used over the past four years to store accommodation containers, work equipment, and materials.

Over the next three years, the area will be reclaimed so that it can be used for agriculture again. The next step now focuses on connecting the entire gas compressor station to the control center of terranets bw. Work is in full swing and initial tests have been successful. After the test phase is completed, the compressor units can be fully controlled from the control center at terranets bw. Trial operations will begin in January, the final phase of the project before commissioning.

Spring is just around the corner, so reforestation work has begun on and around the Mörsch compressor station site. Trees have been planted around the station area over the past few days. Wild vines will bloom on the area in the future.

Work on commissioning the compressor units is progressing rapidly. At the same time, preparations are being made to deconstruct the construction site facilities.

Once the containers and work equipment have been removed, the area will be restored so that it can once again be used for agricultural purposes.

Once the fence around the site has been installed, the final survey of the site and the area required by terranets bw for the operation of the compressor station will take place. In addition, the electric charging station on the site has been put into operation.

In mid-December, Sebastian Schrempp, mayor of Rheinstetten, visited the new Mörsch gas compressor station to see it for himself. Project manager Susanne Kurschat and Dr. Daniel Pietzka, head of planning, projects, and construction at terranets bw, provided information on the progress of the Mörsch gas compressor station. Shortly before the visit, the entire station site, including secondary facilities, was filled with gas. The station site is now filled with gas, which is an important requirement for the commissioning of the compressor units.

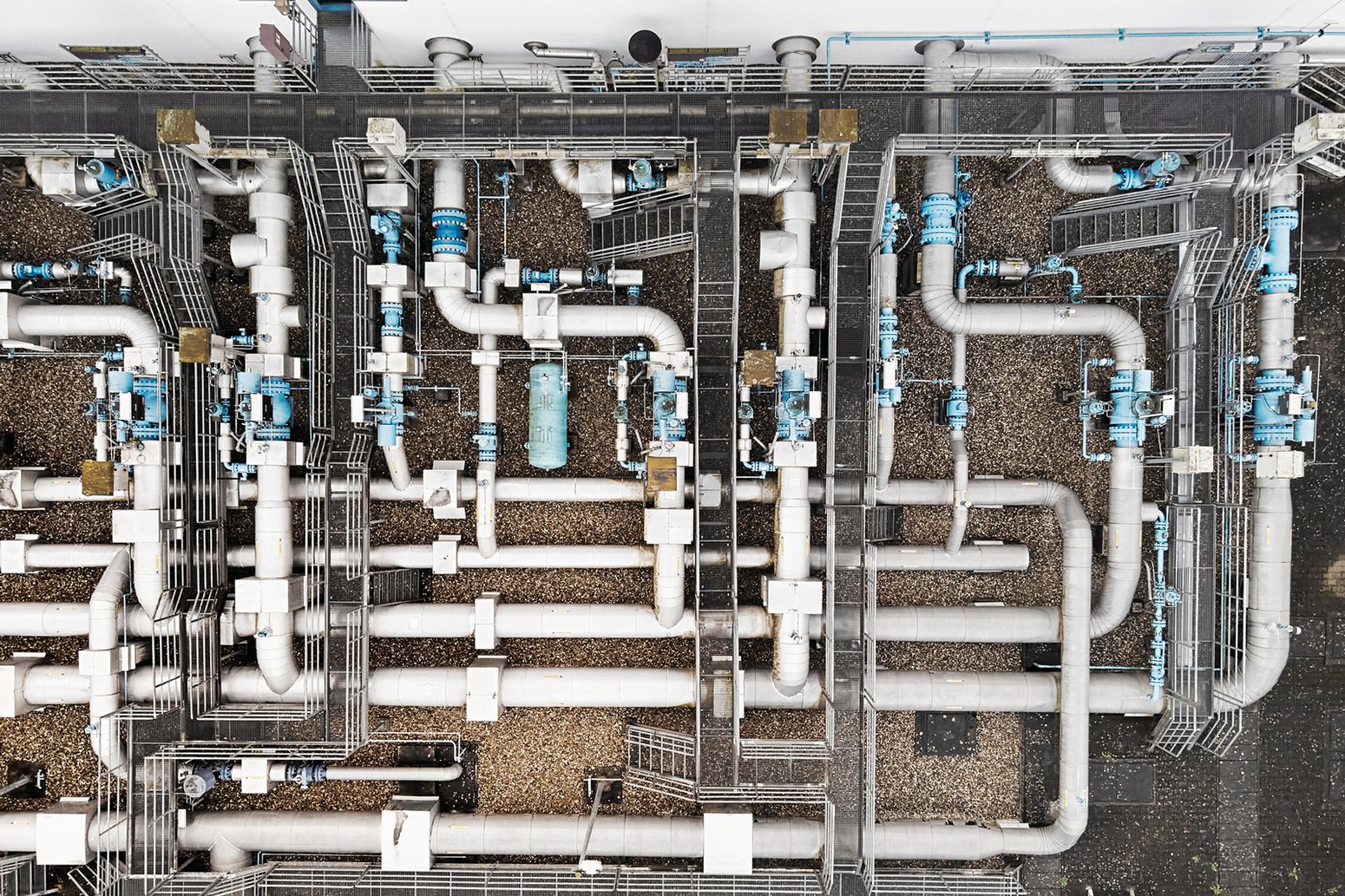

Control technology, armature groups, gas pressure control systems, and electrical engineering have also been completed. There has also been a lot of activity on the outdoor grounds of the Mörsch gas compressor station in recent months: the paving has been completed and the asphalt work is progressing. The missing top layer will be applied in the spring. The additional construction road for the valve group has been dismantled. The area around the Mörsch gas compressor station is already being prepared for planting in the spring.

A lot has been happening around the new gas compressor station Mörsch in Rheinstetten in recent months. The asphalt work that has started at the gas compressor station Mörsch is visible from the outside. In addition, permanent fences are being erected to replace the construction fences that previously bordered the site.

The lighting for the facility is also gradually being installed. To protect the environment, no permanent lighting will be installed. Instead, safety lamps with motion detectors and insect-friendly lighting will be used within the facility. The aerial photos also show the roof area of the plant building, which will be further greened - another measure to protect the environment.

Spring is on its way and the outdoor facilities of the new gas Mörsch compressor station can be completed by summer. The site is being filled in to further reduce the gradient to Panzerstrasse and the site roads are being completed. Embankments and vegetation are being planted and a fence is being erected around the new Mörsch gas compressor station.

Progress is also being made on the inside: all four machine halls are electrically and mechanically complete and ready for gas testing. The fire and gas detection systems have also been installed.

Work on the interior of the plant building has also progressed. Following the interior work, the IT and telecommunications systems are currently being installed.

A lot has happened in the last few months: The piping in the four machine halls has been finished. This means that all the turbines are now electrically and mechanically complete. After oil flushing, they are ready for hot commissioning. Commissioning of the auxiliary plant is also progressing. The medium voltage system was the first to be successfully approved by TÜV in November, while other systems are currently being completed and prepared for acceptance. The last remaining work is being carried out on the energy centre building. Interior work on the operations building is also well advanced. The building is expected to be fully completed in March 2024.

In October 2023, the leak test of the last outdoor pipelines was successfully completed. Much remains to be done. More cables need to be laid and many ancillary systems need to be commissioned before the machine units can be tested. As soon as the power supply is stable, the entire plant will be fumigated.

The exterior is also taking shape: The site is gradually being filled in. The station roads have also been laid. Roads and fences should be completed by spring.

Netze Südwest, the largest regional gas distribution network operator under the state regulatory authority in Baden-Württemberg, is directly connected to the transport network of terranets bw with its networks in North Baden and Upper Swabia. With its work and its facilities at around 74,000 exit points, it ensures a secure and reliable gas supply for its customers.

To minimize the impact on nature and the environment, terranets bw takes numerous precautions. The existing natural and landscape conditions were thoroughly examined and considered in the planning of the Mörsch gas compressor station in Rheinstetten (Karlsruhe district).

Based on the investigation results, measures were derived to avoid or reduce environmental impacts. Unavoidable, permanent impacts are compensated through appropriate measures.

- Enhancement of the existing forest by combating late-flowering bird cherry and planting oak forests

- Enhancement of a pond

- Enhancement of the landscape protection area

- Reforestation to replace lost forest areas

- Protection of bat maternity roosts

- Installation of nesting boxes and breeding aids for birds and bats

- Removal of currently sealed surfaces

- Adjustment of the compressor station’s location to preserve as much of the forest edge as possible as a guiding structure for bats and as a natural visual barrier

- Noise protection concept to reduce noise emissions

- Protection of reptiles and amphibians during the construction period

- Installation of a green roof

Questions and answers

What is a gas compressor station?

What is a gas compressor station?

In a gas compressor station, gas is compressed and its pressure increased. This means more gas can be transported through the pipeline. The shipping capacity of the pipeline increases – and therefore also security of supply for consumers. In Germany, there are about 70 gas compressor stations that are operated in particular in the case of increased capacity demand – which is primarily in winter time.

How does a gas compressor station work?

How does a gas compressor station work?

Travelling through underground pipelines, gas reaches the compressor station with a pressure of 40 bar. Firstly, dust and moisture are filtered out. And then the gas is passed into the compressor and there brought to the required pressure. A turbine or electric engine supplies the energy needed for the compression process.

During compression, the gas heats up to 70 °C and is therefore fed through gas coolers that cool it back down to operating temperature. The gas is then fed through a measuring section before being injected back into the transmission system of terranets bw with a pressure of 80 bar.Why is a gas compressor station needed on the Nordschwarzwald pipeline?

Why is a gas compressor station needed on the Nordschwarzwald pipeline?

Regional grid operators connected to terranets bw´s transmission system (e. g. utilities) have been reporting constantly increasing demand for gas shipping capacity for years. By 2030, the demand in Baden-Württemberg will rise by about 30 % compared to 2020. For the entire terranets bw network, a demand increase of 24 percent is expected. The reason for this trend is the fuel switch from coal and oil to gas, the related rising demand from gas-fired power stations and in the heating market as well as new connections and developments.

The Federal Network Agency has confirmed that the new construction of the Mörsch gas compressor station is needed for security of supply in Baden-Württemberg with the approval of the Gas Network Development Plan 2022. All Network Development Plans are published on the website of the association of transmission system operators at www.fnb-gas.de.

How was the location for the Mörsch gas compressor station selected?

How was the location for the Mörsch gas compressor station selected?

Site selection was preceded by detailed studies, in which terranets bw took into account legal stipulations and technical requirements as well as a wide range of influencing factors. These include protected areas, distances to residential buildings, land use plans and information provided by the communities. After intensive assessment and in close exchange with local authorities and associations, a location was selected for the new compressor station. Special consideration was also given to maintaining a low visibility of the system. During the approval process, the Freiburg Regional Council, as competent approval authority, decided that the station could be built and operated at the proposed site.

Who approves construction and operation of a gas compressor station?

Who approves construction and operation of a gas compressor station?

Construction and operation of gas compressor station requires public-law permission according to the Federal Immission Control Act (German: BImSchG). The competent approval authority is the Freiburg Regional Council. In order to achieve broad consensus with all stakeholders, terranets bw involved the affected communities and other stakeholders at an early stage.

Who is responsible for building the Mörsch gas compressor station?

Who is responsible for building the Mörsch gas compressor station?

Transmission system operators in Germany are obliged to guarantee a future-proof supply of gas by developing their network. As an independent transmission system operator for gas in Baden-Württemberg, terranets bw is responsible for building the Mörsch gas compressor station.

How much space does a gas compressor station need?

How much space does a gas compressor station need?

When operational, the planned Mörsch gas compressor station needs an area of approx. 2.4 ha (24,000 m²). This is roughly equivalent to the size of three football fields. During construction, additional land is temporarily needed for setting up the construction site and for the storage of building equipment and material.

What restrictions can be expected during the construction phase?

What restrictions can be expected during the construction phase?

For construction, additional areas are temporarily occupied for setting up the construction site and for the storage of building equipment and materials.

An increased volume of traffic can be expected because of deliveries along the access roads. As soon as the building works have been completed, the areas that were temporarily occupied (for setting up construction site and storing building equipment and material as well as the access roads) will be restored to their original state and can be used for their original purpose once again. Damage to land and vegetation caused by this temporary use will be compensated at the fixed rates.

Is noise pollution expected near the Mörsch gas compressor station?

Is noise pollution expected near the Mörsch gas compressor station?

When operating a gas compressor station, the noise pollution at the fence of the system corresponds to about 60 dB(A). This is comparable to a television set at room volume. The noise pollution at a distance of 350 m is then about 35 dB(A). This complies with statutory limits for a quiet residential area. The distance between the planned gas compressor station and the nearest residential area will be more than 350 m. Generally, the local noise situation is largely influenced by the neighbouring roads (A5, L566, K3581).

During the planning process, expert opinions are prepared regarding the noise emissions that can be expected. The results of these expert opinions serve to determine and dimension the noise protection measures required to comply with the statutory noise protection limits.

Who checks the safety of the Mörsch gas compressor station?

Who checks the safety of the Mörsch gas compressor station?

Operation and maintenance are carried out by qualified specialists employed by terranets bw. The Mörsch gas compressor station is monitored and controlled, as is the whole transmission system of terranets bw, by a dispatching centre that is manned 24/7.

Compliance with legal and technical regulations is monitored by the state energy supervisory authority. Modifications must be inspected and signed-off by state certified experts. The supervisory authority for terranets bw is the State Mining Directorate (German: Landesbergdirektion) of the Freiburg Regional Council.

How long will it take to construct the gas compressor station?

How long will it take to construct the gas compressor station?

Constructing and commissioning a gas compressor station normally take about two years. This period includes land development, erecting the buildings, installing the compression equipment as well as restoring open spaces on the station site.

Construction began in the autumn of 2021 after receiving approval. Commissioning is planned for 2025.

How does terranets bw guarantee that the surroundings and environment are protected during construction?

How does terranets bw guarantee that the surroundings and environment are protected during construction?

Throughout the whole planning and construction process, terranets bw takes numerous precautions to minimise the impact on nature and on the environment. At the start of the planning phase, terranets bw takes a detailed inventory of the landscape and surrounding nature and assesses the impact on plants, animals, ground, water, climate/air, landscape and people as well as on cultural assets.

Measures were derived from the study results to avoid and reduce the impact on the environment, which meant that the compressor station location, access and gas connection pipeline were adapted to avoid disruption of the forest edge as far as possible. The edge of the forest serves as a guiding structure for bats and additionally acts as a natural screen for the gas compressor station. Permanent lighting at the gas compressor station will also be avoided and insect-friendly lighting will be used. Measures to protect reptiles and amphibians will be implemented during the construction phase.

Unavoidable, permanent impairments will be compensated by corresponding measures (compensation measures). In addition to planting new trees, nesting boxes and hatching aids for birds and bats are planned for example, as well as upgrading a humid biotope in Rheinstetten.

What emissions are produced in operation?

What emissions are produced in operation?

Derived from empirical values for operating times at the terranets bw compressor stations, weather conditions over the last few years and the planned control of the network after commissioning the new compressor station, terranets bw currently estimates 500 to 2,000 operating hours per year. This assumption includes the sum of operating hours for all machine units (three gas turbines, one electric engine). The local CO2 emissions of one machine unit operated with a gas turbine amount to about 4,000 kg per operating hour. By using the electrically-powered machine unit, the local CO2 emissions are reduced. The level of CO2 emissions depends on the respective distribution of electricity generation. Using only machine units that are powered by a gas turbine produces 2,000 t to 8.000 t of local CO2 emissions per year.

terranets bw also uses a recompressor system at the Mörsch gas compressor station in Rheinstetten (Karlsruhe district). This is an additional measure taken by terranets bw to avoid methane emissions when operating the system.

Small amounts of methane escape at the drive shafts of the compressor units, which cannot be avoided completely. However, this methane is collected in a collection system and injected back into the transmission system with the recompression system. All other components of the compression system are technically sealed so that no methane emissions can escape.

![[Translate to English:] Unser Telekommunikationsnetz](/fileadmin/_processed_/4/8/csm_Telekommunikation_Kabel_Unschaerfe_blau_gelb_terranets-bw_e68fc06931.jpg)

![[Translate to English:] terranets bw / Für Kunden / Telekommunikation](/fileadmin/_processed_/6/7/csm_231222_Mitarbeitender_am_Schaltschrank_6_kl_0cca01e205.jpg)

![[Translate to English:] Kundenportal ConnectCapacity](/fileadmin/_processed_/c/3/csm_231222_Mitarbeitende_der_IT_Computer_8_kl_3266995988.jpg)

![[Translate to English:] terranets bw Unternehmen Visionen](/fileadmin/user_upload/Content/Unternehmen/Visionen/terranets_bw_Mitarbeitende_Brainstorming_1.jpg)

![[Translate to English:] terranets bw: Wasserstoff für Baden-Württemberg](/fileadmin/_processed_/2/3/csm_Wasserstoff_Inititative_Logo_Energiezukunft_8904d74570.jpg)

![[Translate to English:] terranets bw: Sehen Sie sich unsere Stellenangebote an!](/fileadmin/_processed_/c/0/csm_240507_Mitarbeitende_im_Gespraech_3_bcf21346f8.jpg)

![[Translate to English:] Arbeiten bei der terranets bw](/fileadmin/user_upload/Content/Karriere/terranets_bw_Karriere_Arbeiten-bei-Terranets_3zu2.jpg)

![[Translate to English:] Die Standort der terranets bw](/fileadmin/user_upload/Content/Karriere/terranets_bw_Was-wir-tun_Scharenstetten_3zu2.jpg)

![[Translate to English:] Studium, Ausbildung oder ein Praktikum bei der terranets bw](/fileadmin/_processed_/2/f/csm_TERRANETS_Bild_Fuer-Praktikanten-und-Auszubildende_Fuer-Schuelerinnen_3zu2_360e1e705d.jpg)

![[Translate to English:] terranets bw: Netzausbauprojekte](/fileadmin/_processed_/4/0/csm_Absenken_Rohrstrang__3__67f60716af.jpg)

![[Translate to English:] terranets bw Mediathek](/fileadmin/_processed_/2/2/csm_terranetsbw_Flugtafel_3_c6937e947f.jpg)

![[Translate to English:] Gasverdichterstation Nordschwarzwaldleitung: Drohnenaufnahme Außenbereich](/fileadmin/_processed_/b/6/csm_240820_Drohnenaufnahme_VDS_NOS_Rheinstetten_5_dd58e8f332.jpg)

![[Translate to English:] Gasverdichterstation Nordschwarzwaldleitung: Außenbereich](/fileadmin/_processed_/0/3/csm_240820_Baufortschritt_VDS_NOS_Rheinstetten_3_7162872b02.jpg)

![[Translate to English:] Gasverdichterstation Nordschwarzwaldleitung: Letzte Vorbereitungen für den Probebetrieb mit Gas](/fileadmin/_processed_/2/8/csm_240321_Baufortschritt_Drohnenansicht_VDS_NOS_Rheinstetten_1_17195533d2.jpg)

![[Translate to English:] Gasverdichterstation Nordschwarzwaldleitung: Letzte Vorbereitungen für den Probebetrieb mit Gas](/fileadmin/_processed_/8/d/csm_240321_Baufortschritt_VDS_NOS_Rheinstetten_23_bbfe589e02.jpg)

![[Translate to English:] Standort der Gasverdichterstation Rheinstetten](/fileadmin/user_upload/Content/Unsere-Netze/Netzausbauprojekte/Gasverdichterstation_Nordschwarzwaldleitung/terranets_bw_Standort_VDS_NOS_ae035baba1.jpg)